Z4R – a recycled material

As society constantly evolves and customers become more aware, it is essential to meet the demands placed upon us. Our mission is to offer our customers products that meet their needs. With Z4R, the customer receives a pre-galvanized material with a low climate footprint that withstands outdoor environments and self-heals when cut.

A material with high corrosion resistance

The material Z4R has the same properties as our material Z4, with the difference that Z4R is based on a high proportion of recycled material. The surface treatment corresponds to a minimum of 85 µm, compared to a traditional hot-dip galvanized product which is normally a maximum of 60 µm.

Traditional hot-dip galvanized cable ladder after 1050 hours salt test.

Traditional hot-dip galvanized cable ladder after 1050 hours salt test.MP bolagen Z4 material for cable ladders

Methods for galvanizing

Electro-galvanization is a process in which a thin layer of zinc coating is applied to the surface of a metal, typically steel or iron, to protect it from corrosion. The process involves immersing the metal in an electrolyte solution (a solution that conducts electricity) along with zinc anodes (zinc material that releases zinc ions). When an electric current passes through the bath, the zinc ions react with the metal surface, forming a dense zinc coating on the surface of the metal.

Pre-galvanization This is a method where, for example, a steel coil passes through a bath of zinc for a short period. Air knives or mechanical drying remove the excess, resulting in a good surface finish. The coating on the zinc layer is slightly thinner than hot-dip galvanization, and the sheet is then processed into products.

Hot-dip galvanization, also known as immersion galvanization, is a process where a processed product is dipped into molten zinc to create a protective zinc layer on the surface. The finished product now has a thin but highly durable zinc layer that shields the metal beneath it from corrosion.

Low environmental impact

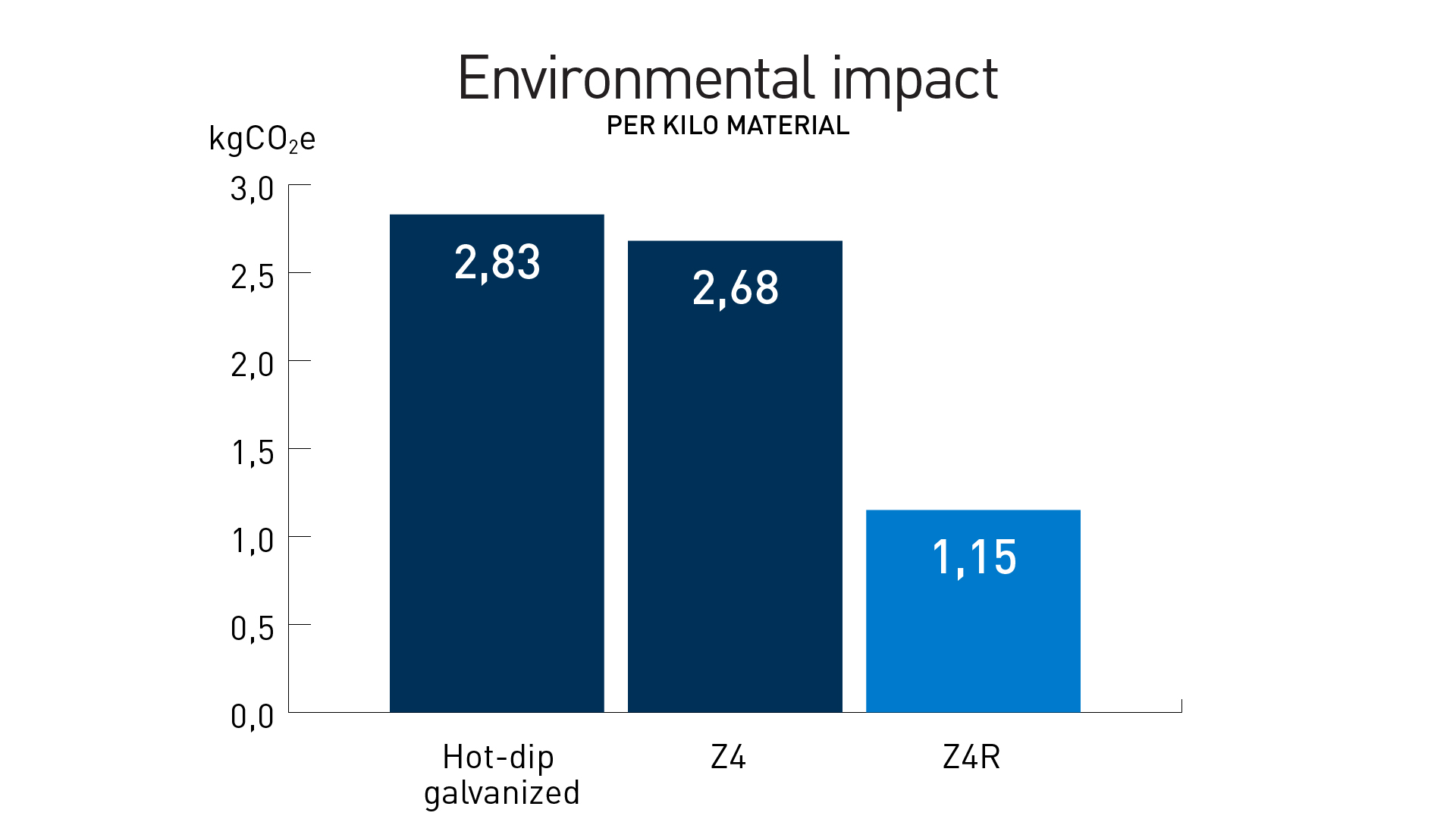

Our ladders made from the material Z4R have over 60% lower carbon footprint compared to our traditionally hot-dip galvanized ladders of equivalent design. Z4R is produced with 100% renewable energy. It is based on a high proportion of recycled steel and ore pellets melted in electric arc furnaces.

You can find EPD values on the product pages for our in-house manufactured products. All our EPD values are verified by an independent third party.