MP bolagen and SSAB - partners for fossil-free steel.

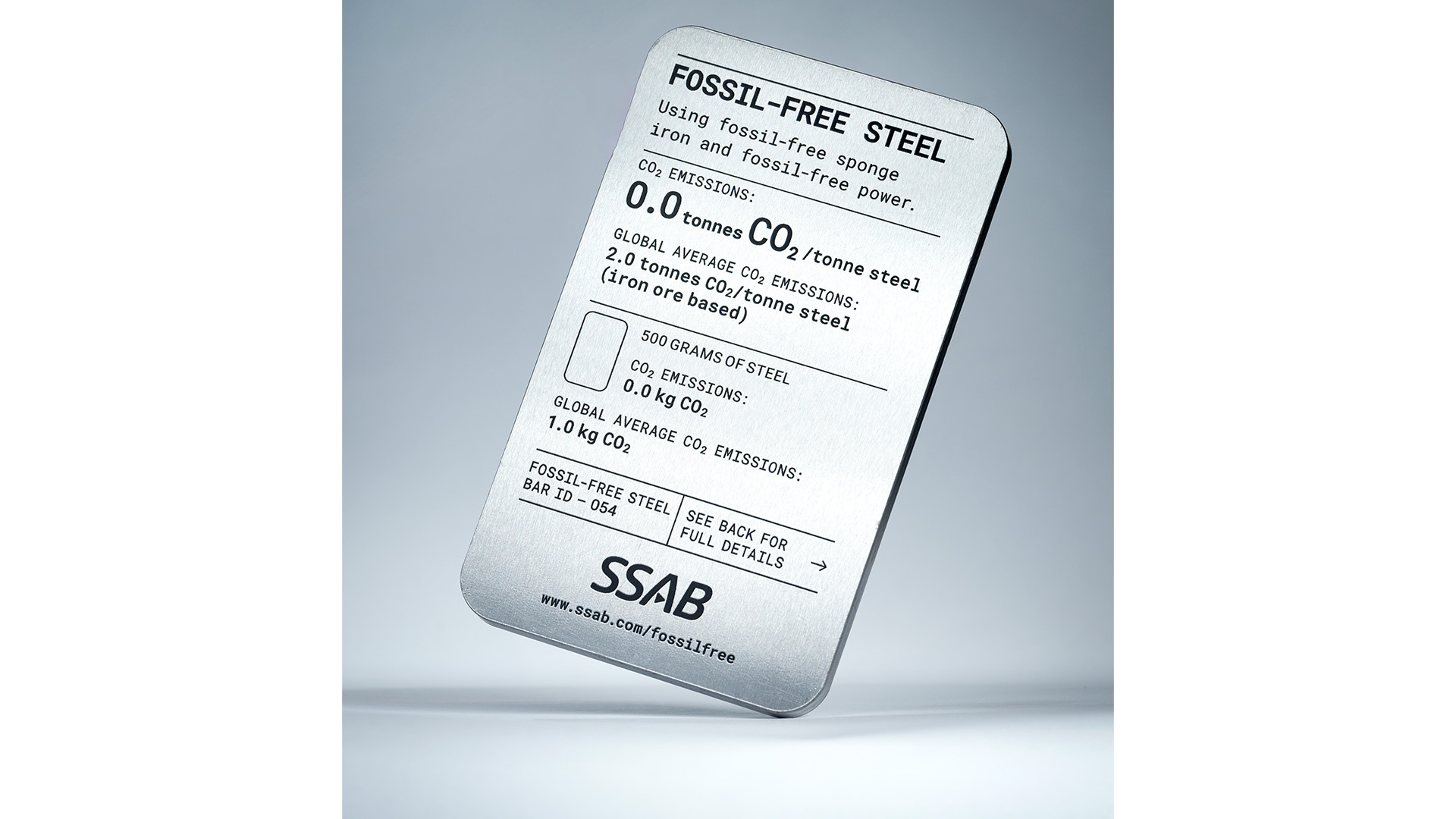

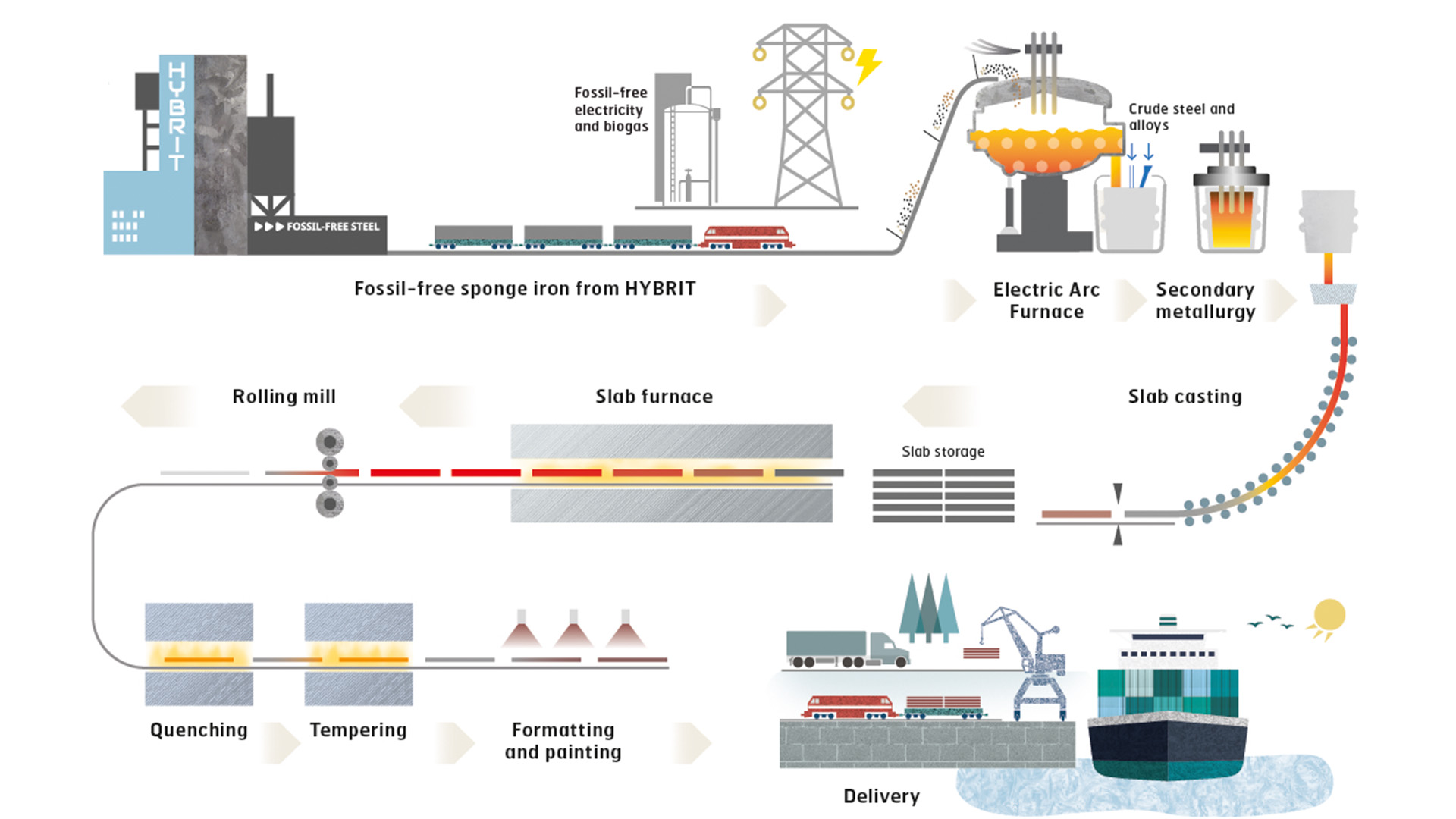

We aim to minimize our carbon footprint and to be part of the transition to a fossil-free value chain. The fossil-free steel made by SSAB is based on revolutionary HYBRIT technology using fossil-free hydrogen instead of fossil fuels like coke, coal and oil.

When fossil-free steel is available in 2026, we will start to use it in our products. We are happy to tell you more and to discuss how, together, we can create a low-carbon or fossil-free value chain all the way from the iron ore mine to the end-customer!

With the HYBRIT initiative, SSAB, LKAB, and Vattenfall aim to create a completely fossil-free value chain from mining to finished steel, using fossil-free pellets.

What is HYBRIT?

In 2016, SSAB, LKAB (Europe’s largest iron ore producer) and Vattenfall (one of Europe’s largest energy companies) joined forces to create HYBRIT – an initiative that endeavors to revolutionize steelmaking. Using HYBRIT® technology, SSAB aims to replace coking coal, traditionally needed for ore-based steelmaking, with fossil-free electricity and hydrogen. The result will be the world’s first fossil-free steelmaking technology, with virtually no carbon footprint. Our goal is to reduce Sweden’s CO2 emissions by 10% and Finland’s by 7%.

In July, SSAB Oxelösund rolled the first steel produced using HYBRIT technology, i.e., reduced by 100% fossil-free hydrogen instead of coal and coke, with good results. The steel is now being delivered to the first customer, the Volvo Group.

Why fossil-free steel?

-

Reduce your footprint with low CO2 steel.

-

Reduce CO2 emissions in the use phase.

-

Be part of a fossil-free value chain.